How to Design and Create a Custom PJs Collection for Your Apparel Brand?

- Lydia Design Studio

- Aug 19, 2025

- 5 min read

In recent years, sleepwear and loungewear have evolved from simple bedtime clothes to stylish essentials. As people increasingly prioritize comfort, versatility, and self-care in their wardrobes, the demand for high-quality, thoughtfully designed pajamas has surged. This change in consumer habits creates a significant opportunity for clothing brands.

However, creating a custom PJ collection isn't just about slapping your brand logo on a shirt and calling it a day. It’s about crafting garments that blend comfort, functionality, and brand identity in a way that resonates with your target audience.

From choosing the right fabrics and fits to understanding how production works behind the scenes, there’s a lot to get right, and that’s exactly what we’ll cover in this blog post.

Today, we’ll walk you through the entire process of designing and producing your own custom pjs line (from initial ideas and sketches, all the way to sourcing, sampling, manufacturing, and packaging).

Let’s get started!

Action Plan for Your Custom PJs Collection

Understanding the Market for Custom Print Pajamas

Designing Your Pajama Sets

Sourcing Materials and Trims

Pattern-Making and Sample Development

Labelling, Branding, and Packaging

Understanding the Market for Custom Print Pajamas

Before designing your custom PJ collection, it’s essential to understand the market you’re entering. Sleepwear and loungewear have gained serious traction in recent years. Customers now expect more than just basic sets; they’re looking for pieces that feel good, look polished, and align with their personal style.

This demand has opened up several niche opportunities worth exploring, including gender-neutral styles for inclusivity, maternity-friendly designs with functional features, family-matching sets, and sustainable apparel options made from eco-conscious fabrics such as bamboo or organic cotton.

To position your collection effectively, study what other brands are offering. Analyze their designs, pricing, and customer feedback. What’s working and what’s missing? This will help you identify market gaps you can fill.

Designing Your Pajama Sets

Once you've defined your concept and market position, the next step is to bring your apparel concepts to life. This is where your custom pajamas collection starts to take shape — both creatively and technically.

Start by deciding on the types of PJ sets you want to offer. Your selection will depend on your target audience, seasonal relevance, and the overall style and theme of your collection.

Here are some popular options:

Button-down shirt + pajama pants: A classic, polished look that works well for both men’s and women’s styles. Ideal for colder seasons or premium collections.

Oversized tee + shorts: Perfect for summer or casual loungewear. These sets appeal to younger demographics or customers looking for relaxed fits.

Robes + nightgowns: Great for spa-inspired or luxury collections. These styles allow more fabric play and can be made from flowy, elegant materials like silk or modal.

Mix-and-match capsule sets: These sets are designed for flexibility. Customers can pair tops and bottoms as they like, which adds personalization to your collection and encourages multiple purchases.

Sourcing Materials and Trims

Choosing the right fabric is one of the most important steps in building a successful pajama set collection. Your material impacts everything — from comfort and durability to price point and brand perception. It’s not just about how the fabric looks; it’s about how it performs in real life.

Some commonly used fabrics for sleepwear include:

Cotton: Soft, breathable, and easy to care for. It works great for all-season basics.

Modal: Lightweight and silky, ideal for premium-feel pajamas.

Bamboo: Naturally antibacterial, eco-friendly, and moisture-wicking.

Viscose: Smooth and drapey, good for elegant nightwear.

Flannel: Warm and cozy, perfect for winter collections.

Satin: Satin blends are sleek and luxurious. Great for elevated or romantic styles.

TENCEL™: A sustainable option that’s breathable, soft, and biodegradable.

Also, consider the fabric's performance. Think about shrinkage after washing, stretch and recovery, breathability, softness, and how well it holds dye or prints.

If sustainability is a part of your brand story, consider options such as GOTS-certified organic cotton, recycled fabrics, or deadstock materials to reduce waste and appeal to eco-conscious customers.

In addition to fabric, focus on high-quality trims and extras (like buttons, piping, drawstrings, and elastic waistbands) as they play a key role in both function and aesthetics.

Pattern-Making and Sample Development

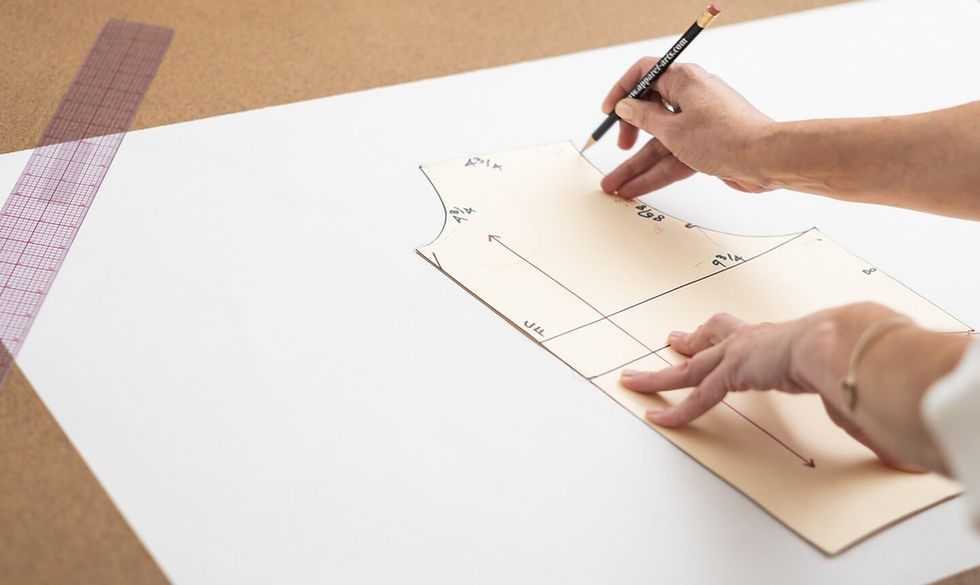

Once your fashion tech pack is ready and materials are selected, the next phase is pattern-making and sample development. This pre-production stage is critical for getting the fit, shape, and construction right before you move into bulk manufacturing.

The process starts with creating patterns based on your tech pack. A pattern is the template used to cut each piece of fabric that makes up your garment. It begins with a base size (usually medium) and is adjusted through a process called pattern-grading to create patterns for other sizes (small, large, etc.). Proper grading ensures your custom PJs fit consistently across your size range.

Once the pattern is finalized, the sample development phase begins. This usually includes:

First prototype: An initial sample to test the design, fabric behavior, and construction.

Fit sample: Used to assess sizing, proportions, and how the garment looks on a real body.

Pre-production sample (PPS): The final, approved version that reflects exactly what will be produced in bulk.

During sample review, clothing manufacturers and brand owners pay close attention to fit, comfort, fabric behavior after washing (shrinkage, distortion), construction issues (puckering seams, uneven stitching), and trim details (buttons, waistbands, drawstrings).

Labelling, Branding, and Packaging

Branding, packaging, and labeling are the final touches that tie your pajama collection together.

Let’s start with labels. Every garment needs basic labels, but how you approach them can elevate your product.

Woven labels: Durable and high-end in appearance, great for necklines or outer branding.

Printed labels: Lightweight and soft, often used for inner neck prints.

Heat-seal labels: Applied without stitching, ideal for seamless comfort (especially for sleepwear).

In addition to main labels, consider custom swing tags for branding and storytelling, wash care labels with fabric content and care instructions, and size tags that are easy to read and neatly placed.

Lastly comes the packaging of your personalized pajamas collection. Choose a packaging style that resonates with your brand identity. You can also go for eco-friendly packaging material that isn’t harmful to the environment and is also appreciated by consumers.

Choosing the Right Clothing Manufacturer for Your Custom Pajama Line?

Now that you know how to design custom pajamas along with the key details, here comes the most important question: how to choose the best clothing manufacturer for your apparel collection?

Choosing the right manufacturing partner is one of the most critical decisions you’ll make when launching your custom PJs collection. The right clothing producers won’t just create your garments; they’ll help you avoid costly mistakes, ensure consistent quality, and bring your vision to life with precision.

Here’s what you should look for:

Experience with loungewear: You want a manufacturer who understands the nuances of sleepwear, like fabric comfort, fit, and construction techniques.

Low MOQ flexibility: MOQ (Minimum Order Quantity) is a crucial parameter in clothing manufacturing. This is especially important for startups testing the market or launching limited collections.

Full-service capabilities: From design development and pattern making to sampling and production — having it all under one roof streamlines the entire process.

Quality control processes: Reliable inspection standards help ensure your products meet expectations.

This is where Lydia Design Studio stands out. As a full-service clothing manufacturer based in Atlanta, we specialize in helping both emerging and established brands create premium loungewear collections from the ground up.

Our team works closely with clients through every stage (from design to final production), ensuring:

Quick and clear communication, with no time zone delays

In-house support for design, material sourcing, pattern making, and sampling

Reliable timelines and consistent quality, with transparency throughout the process

Whether you're just starting or scaling an existing brand, Lydia Design Studio is equipped to support your goals with the expertise, flexibility, and attention your collection deserves.

Book a free design consultation with us and bring your vision to life!

.png)